| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HLLP |

| Model Number : | DN2412 |

| Price : | US$ 0.4-5 per piece |

| Payment Terms : | T/T, L/C |

| Supply Ability : | 100000 sets per month |

| Delivery Time : | 10-20 days |

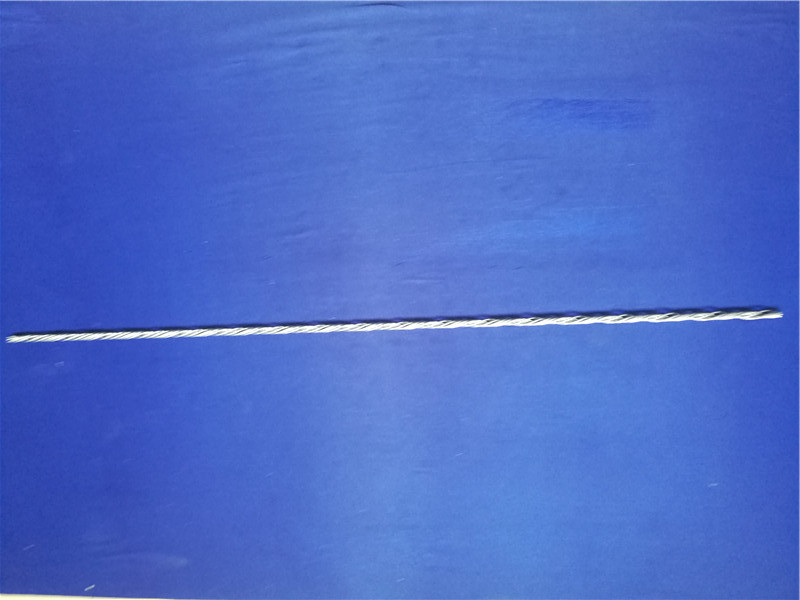

Guy grip dead end

The material used to create the Guy Grip dead end is usually the same material used in the harness that attaches to it. Commonly used materials include galvanized steel wire and aluminum-clad steel wire. The purpose of this product is for single pole in power distribution construction projects. The grip provided by this product is even and prevents twisting of strands. In addition, the clamping strength is guaranteed to be at least 100% of the ultimate tensile strength (UTS) of the strands. During the installation process, it is crucial to proceed with caution to ensure success. It should be noted that this product is intended for use by trained and skilled professionals only.

| Preformed Dead End for Galvanized steel strand | ||||||||

| Discription | Dia.Range | Type | Wire Size | No.of | Material | Length | Weight | Color Code |

| (mm) | (mm) | rods | (mm) | (kg) | ||||

| EHS 3/16 | 4.7 | DN 2409 | 1.8 | 5 | Galvanized steel | 508 | 0.11 | RED |

| EHS 1/4 | 6.30 | DN 2410 | 2.18 | 5 | Galvanized steel | 635 | 0.2 | YELLOW |

| EHS 5/16 | 7.94 | DN 2411 | 2.54 | 5 | Galvanized steel | 788 | 0.34 | BLACK |

| EHS 3/8 | 9.53 | DN 2412 | 3.02 | 5 | Galvanized steel | 889 | 0.54 | ORANGE |

| EHS 7/16 | 11.11 | DN 2413 | 3.51 | 5 | Galvanized steel | 966 | 0.8 | GREEN |

| EHS 1/2 | 12.70 | DN 2414 | 4.37 | 5 | Galvanized steel | 1245 | 1.59 | BLUE |

| EHS 9/16 | 14.20 | DN 2415 | 4.78 | 5 | Galvanized steel | 1340 | 2.04 | YELLOW |

| EHS 5/8 | 15.88 | DN 2416 | 5.18 | 5 | Galvanized steel | 1626 | 2.9 | BLACK |

| Left hand lay is standard | ||||||||

what is preformed dead end?

To increase the grip of the preformed rods on the strand or wire,

glue several preformed rods together as needed and grit the parts

that come into contact with the strands.

In order to facilitate the installation of the sleeve U-shaped

clamp, it is necessary to loosen a certain length in the middle of

the glued preform, and take the center of the loosened section as

the reference, and fold the preform in half according to the

required radius to form two legs. The products made after this

process are called prefabricated dead ends.

Prefabricated dead ends are widely used in power transmission and

distribution lines. Its main function is to tension the wire and

install it on the terminal tower. It bears the running tension of

the line and other additional loads. For various types of wires,

stranded wires or optical cables, etc., different types of

preformed dead ends are designed for different occasions. Due to

its special structure, it has excellent product performance

compared with traditional bolt or compression clamps:

1. The stress of clamping the wire is evenly distributed along the

winding wire section to ensure the clamping of the wire and avoid

stress concentration causing damage to the wire.

2. The fixture structure installed on the wire can improve the

vibration resistance of the wire and prolong the service life of

the wire.

3. It is easy to install. The construction personnel only need to

ensure that the wire clamp is evenly wound on the wire, without any

tools, and the installation quality is easy to ensure.

|